Welcome to our company

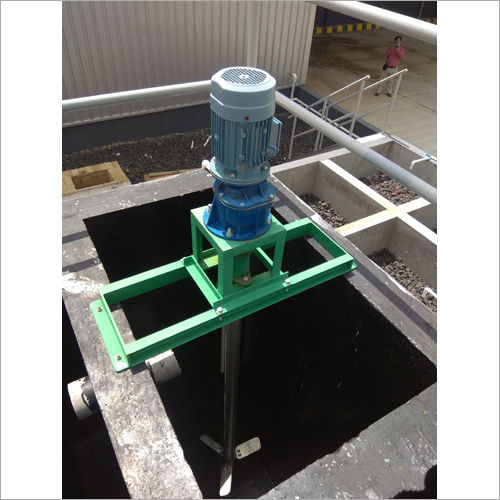

Surface Aerators

10000 INR/Bag

Product Details:

- Water in conductivity 500-1000 S/cm

- Efficiency (%) Above 90%

- Flow Rate 10 300 m3/hour

- Water Out Conductivity 50-80 S/cm

- Power Consumption 1.5 kW to 18 kW

- Noise Level Below 75 dB

- Usage & Applications Effluent Treatment Plants, Lakes, Fish Ponds, Industrial Wastewater

- Click to view more

X

Surface Aerators Price And Quantity

- 1 , , Plant

- 10000 INR/Bag

Surface Aerators Product Specifications

- Direct / Geared

- 50 Hz / 60 Hz

- Stainless Steel / FRP

- 6.5 8.5

- Up to 90% water recycling capability

- Up to 99%

- Industrial and municipal wastewater

- Submersible / Floating

- 2 HP to 25 HP

- N/A (Aeration Process)

- 380-440 V

- Floating / Fixed

- 500-1000 S/cm

- Surface Aerator

- Above 90%

- 1.5 kW to 18 kW

- 50-80 S/cm

- 10 300 m3/hour

- 1000 500,000 Liters

- Electric

- Automatic

- Surface Aeration, Mechanical

- Below 75 dB

- Effluent Treatment Plants, Lakes, Fish Ponds, Industrial Wastewater

- Low maintenance, High oxygen transfer efficiency, Splash proof motor housing

Surface Aerators Trade Information

- 1 , , Plant Per Day

- 1 Days

Product Description

We are counted among the reputed business entities, engaged in manufacturing Surface Aerators. In petrochemical and water treatment industries these aerators are highly used. To comply with the set industrial norms, we manufacture the aerators using high quality materials. For protection against rust we coat the Fixed Aerators with anti corrosive materials. We offer the aerators at the market leading prices.

Features:

-

Robust construction

-

Easy maintenance

-

Longer working life

Customizable to Your Application

Available with both floating and fixed mounting options, our surface aerators are adaptable to different installation needs. Shaft lengths can be tailored from 900 mm to 2,500 mm, accommodating various tank dimensions and site conditions. The use of SS304 or fiber-reinforced plastic impellers ensures durability, while the modular design supports easy integration in new or existing water treatment setups.

Resilient Performance and Low Maintenance

With ingress protection ratings of IP55 or IP65, heavy-duty ball bearings, and splash-proof motor housings, these aerators are built for harsh industrial and outdoor environments. Anti-corrosive coatings enhance longevity, and the grease-lubricated bearings reduce servicing frequency. The unit operates quietly below 75 dB, ensuring minimal disturbance during continuous operation in effluent plants or fish ponds.

FAQs of Surface Aerators:

Q: How do Surface Aerators with rotor speeds of 8001400 RPM improve water treatment efficiency?

A: Surface Aerators efficiently introduce oxygen into the water by agitating and circulating it, thanks to high rotor speeds of 8001400 RPM. This boosts biological treatment processes, enhances pollutant degradation, and achieves above 90% oxygen transfer efficiency, resulting in cleaner, clearer water.Q: What installation options are available for these surface aerators, and where can they be used?

A: Our surface aerators can be installed using either floating pontoons or fixed structures, making them suitable for a variety of settings including lakes, fish ponds, municipal wastewater facilities, and industrial effluent treatment plants.Q: When is maintenance required, and what makes these aerators low-maintenance?

A: Routine maintenance is minimized due to features like heavy-duty, grease-lubricated ball bearings and anti-corrosive coatings. Inspections are generally recommended twice a year, but the robust construction ensures that frequent maintenance is unnecessary.Q: How is the aerator process controlled and automated?

A: The aerators are automatic in operation, equipped with either Direct-On-Line (DOL) or Star-Delta starters for reliable control. Overload protection and splash-proof housing further ensure safe and uninterrupted performance.Q: What are the primary benefits of using these surface aerators in wastewater treatment?

A: Key benefits include high oxygen transfer efficiency, up to 99% water purity, a long service life of over 10 years, and a high recycle rate of up to 90%. They are energy efficient, offer customizable solutions, and maintain noise levels below 75 dB.Q: Can the surface aerator handle varying power and water volumes?

A: Yes, the aerators accommodate voltage ranges from 380440 V, power consumption from 1.5 kW to 18 kW, and are designed for water volumes ranging from 1,000 to 500,000 litersmaking them flexible for diverse operational needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email