Industrial Water Aerators

Product Details:

- Frequency 50/60 Hz

- Pump Type Centrifugal / Submersible

- Recycle Rate Up to 90%

- Feature Corrosion Resistant, High Oxygen Transfer, Energy Efficient

- Ph Level 6.5 8.5

- Water Out Conductivity < 5 S/cm

- Power Consumption 1 kW 5 kW (Depending on Model)

- Click to view more

Industrial Water Aerators Price And Quantity

- 10000 INR/Bag

- 1 Plant

Industrial Water Aerators Product Specifications

- Industrial/Commercial Water Bodies

- Up to 90%

- Centrifugal / Submersible

- 50/60 Hz

- Stainless Steel / FRP / HDPE

- Corrosion Resistant, High Oxygen Transfer, Energy Efficient

- 6.5 8.5

- < 5 S/cm

- Surface Water Aerator

- Surface Mounted / Floating

- 1 kW 5 kW (Depending on Model)

- Up to 85%

- < 65 dB

- From 0.5 HP to 5 HP

- Effluent Treatment Plant, Aquaculture, Wastewater Treatment

- Industrial Standard

- Mechanical Surface Aeration

- Direct Drive

- Electric

Industrial Water Aerators Trade Information

- 1 Plant Per Day

- 1 Days

Product Description

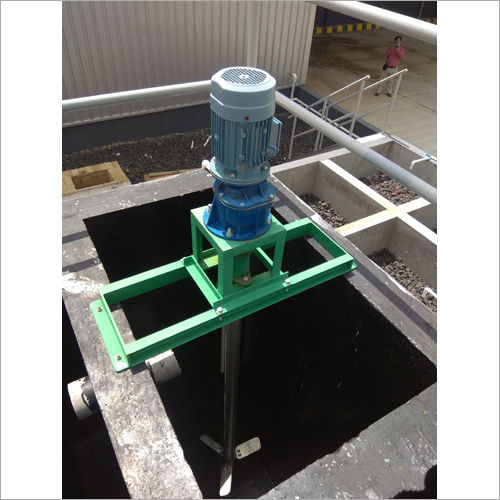

With a wealth of experience and leading market know how, we have established an enviable position of one of the leading manufacturer of Industrial Water Aerators. Equipped with water nozzles, these aerators are used in waste water treatment plants from purification of the sewage water. Our expert workforce uses optimum grade materials, sourced from reliable vendors to manufacture the aerators. We offer the Industrial Water Aerators at the pocket friendly prices to the clients.

Features:

-

Easy maintenance

-

Convenient installation

-

Hassle free performance

Water Aerators

We specialize in providing a wide range of Water Aerators, which finds extensive usage in various industrial applications. In these water aerators, with the help of spray nozzles the water is broken up into small droplets or a thin film, thereby enhancing counter current air contact. Offered at industry leading prices, these are available in different specifications mentioned by our valued customers spread across the nation. These systems are known for their high performance, easy installation, genuine quality and minimum maintenance. Depending upon clients requirements, we offer our products in various technical specifications.

Innovative Aeration Technology

Utilizing mechanical surface aeration, our water aerators effectively improve dissolved oxygen levels, enhancing the health and clarity of industrial or commercial water bodies. The system ensures optimal performance while maintaining water pH between 6.5 and 8.5 and hitting an efficiency mark of up to 85%.

Superior Materials and Construction

Manufactured from premium stainless steel, FRP, or HDPE, these aerators are engineered to withstand harsh industrial conditions and resist corrosion. Whether for floating or surface-mounted installation, durability and longevity are at the forefront, resulting in decreased maintenance and long-term operational savings.

Customizable Power and Capacity

With models ranging from 0.5 HP to 5 HP and adaptive power consumption between 1 kW and 5 kW, our aerators can be tailored to the specific scale and requirements of your facility. The direct-drive mechanism, coupled with centrifugal or submersible pumps, assures consistent and energy-efficient performance across applications.

FAQs of Industrial Water Aerators:

Q: How do industrial water aerators work to improve water quality?

A: Industrial water aerators use mechanical surface aeration technology to introduce oxygen into water bodies, enhancing biological processes that break down contaminants. This results in improved water clarity and quality while reducing odors and promoting a healthier aquatic environment.Q: What types of applications are suitable for these aerators?

A: These aerators are ideal for effluent treatment plants, aquaculture systems, and industrial or commercial wastewater treatment facilities. Their robust design ensures reliable performance in challenging environments where high oxygen transfer and water purity are essential.Q: When should I consider installing an industrial water aerator?

A: Install an industrial water aerator when you need to boost dissolved oxygen levels, control odors, or enhance the treatment capacity of your water body. It is particularly useful during periods of high organic load or when regulatory compliance demands improved water quality.Q: Where can these aerators be installed within a facility?

A: These aerators can be installed on the surface, floated, or mounted within various industrial or commercial water bodies, including tanks, lagoons, and open basins. Their flexible installation options accommodate a wide range of operational layouts.Q: What is the process for commissioning and setting up the aerator?

A: The process involves selecting the appropriate model based on your water bodys size and requirements, positioning the aerator (surface-mounted or floating), connecting it to the electric power supply, and fine-tuning operational parameters, such as speed and oxygenation rates, to achieve optimal performance.Q: How energy-efficient are these aerators and what is their noise output?

A: These aerators are highly energy-efficient, with power consumption adjustable from 1 kW to 5 kW depending on the chosen model. Operating at noise levels below 65 dB, they ensure minimal disruption to the surrounding environment while maintaining high operational efficiency.Q: What are the benefits of using corrosion-resistant materials like stainless steel, FRP, or HDPE?

A: Using corrosion-resistant materials ensures longevity, reduces maintenance demands, and maintains the aerators structural integrity in harsh water conditions. This translates into fewer breakdowns, more stable operation, and lower overall lifecycle costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free