Welcome to our company

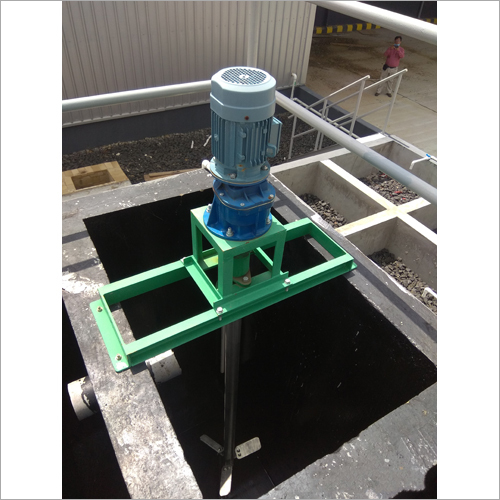

Industrial Wastewater Aerator

10000 INR/Bag

Product Details:

- Pump Type Submersible/Surface

- Frequency 50/60 Hz

- Usage & Applications Effluent Treatment Plants, Chemical Industries, Food Processing, Sewage

- Noise Level <80 dB

- Ph Level 6.5 - 8.5

- Feature Corrosion Resistant, High Oxygen Transfer Efficiency

- Power Consumption 3-7.5 kW

- Click to view more

X

Industrial Wastewater Aerator Price And Quantity

- 10000 INR/Bag

- 1 Plant

- Customizable per site requirements

- 950 - 1450 RPM

- Digital/PLC control panel available

- 0°C to 50°C

- 1.5 to 3.2 kg O2/kWh

- Textile, Chemical, Food & Beverage, Pharmaceuticals, Paper & Pulp, Municipal

- Corrosion-resistant alloy

- IP55 motor protection

- Mechanically driven surface aeration or submersible diffusion

- Floating or fixed mount optional

Industrial Wastewater Aerator Product Specifications

- Submersible/Surface

- Effluent Treatment Plants, Chemical Industries, Food Processing, Sewage

- 50/60 Hz

- <80 dB

- Up to 99%

- Electric

- SS304/SS316

- 6.5 - 8.5

- 3-7.5 kW

- 380V

- Corrosion Resistant, High Oxygen Transfer Efficiency

- Diffused Aeration

- Standard/Customizable

- Automatic

- <10 S/cm

- <4000 S/cm

- 1-50 m3/h

- Wastewater Aerator

- 95%

- Adjustable

- >90%

- Surface Mount/Float Type

- Direct Drive

- Aeration only

- Industrial Wastewater

- Customizable per site requirements

- 950 - 1450 RPM

- Digital/PLC control panel available

- 0°C to 50°C

- 1.5 to 3.2 kg O2/kWh

- Textile, Chemical, Food & Beverage, Pharmaceuticals, Paper & Pulp, Municipal

- Corrosion-resistant alloy

- IP55 motor protection

- Mechanically driven surface aeration or submersible diffusion

- Floating or fixed mount optional

Industrial Wastewater Aerator Trade Information

- 1 Plant Per Day

- 1 Days

Product Description

With the assistance of our advanced methods and imaginative innovation, we are fit for producing and providing of top-quality Industrial Wastewater Aerator to our buyers. This item is mainly utilized in the industrial water for lessening ammonia, controlling bacteria and eliminating carbon dioxide. It is produced by using great quality required materials with the help of innovative technology. Our clients can benefit this Industrial Wastewater Aerator at a market-driving price rate within the promised time frame.

Advanced Oxygen Transfer and Efficiency

With an oxygen transfer rate of up to 3.2 kg O2/kWh and an overall efficiency exceeding 90%, this aerator ensures effective water purification. Its corrosion-resistant impeller and direct drive system provide long-lasting, low-maintenance performance, while digital/PLC control facilitates precise operation in demanding industrial settings.

Versatile Applications and Custom Options

Utilized in effluent treatment plants, chemical manufacturing, pharmaceuticals, food and beverage processing, and municipal wastewater management, the aerator is adaptable to a wide array of site conditions. Customizable dimensions, mounting options, and flow rates make it suitable for both new installations and retrofits. The system meets stringent water quality requirements with output conductivity under 10 S/cm.

Robust Construction and Safety

Made from high-grade stainless steel (SS304/SS316), the aerator withstands aggressive industrial environments. IP55 motor protection ensures reliable performance even in harsh conditions. Automatic operation through digital/PLC control enhances safety and minimizes manual intervention, optimizing staff productivity and system uptime.

FAQs of Industrial Wastewater Aerator:

Q: How does the industrial wastewater aerator improve water quality in effluent treatment plants?

A: The aerator enhances water quality by efficiently dissolving oxygen into wastewater, promoting aerobic microbial activity that decomposes organic contaminants. Its high oxygen transfer rate and advanced diffusion technology support effective and rapid purification, resulting in treated water that meets or exceeds regulatory standards.Q: What industries can benefit from this aeration system and why?

A: Industries such as textiles, chemicals, pharmaceuticals, food and beverage, and municipal sewage plants benefit from this aerator due to its robust corrosion resistance, high efficiency, and ability to handle varying wastewater compositions. Its adaptable configuration makes it suitable for diverse industrial water treatment processes.Q: When should a floating mount be chosen over a fixed mount?

A: A floating mount is ideal for installations where water levels vary or where easy repositioning is required, such as in lagoons or large tanks. Fixed mounts are preferable for stable water bodies or permanent setups. Both options offer optimal performance based on site-specific needs.Q: What is the process for installing and customizing the aerator for a specific site?

A: Upon site assessment, engineers determine the required capacity, mounting type, and dimensional specifications. The aerator is then customizedincluding volume, mounting, and control panel preferencesand installed by trained professionals, ensuring seamless integration with existing treatment infrastructure.Q: How does the control panel enhance the operation of the aerator?

A: Equipped with digital or PLC-based controls, the panel enables automated and precise management of aeration parameters such as flow rate, operational timing, and performance monitoring. This automation reduces manual oversight, optimizes efficiency, and ensures consistent compliance with water quality standards.Q: Where is this aerator manufactured and supplied?

A: This aerator is designed, manufactured, and exported from India, catering to both domestic and international clients through a network of reliable suppliers and exporters. Custom solutions are offered to suit varied global regulatory and operational requirements.Q: What are the main benefits of using this aerator in industrial settings?

A: Key benefits include high oxygen transfer efficiency, corrosion resistance, low power consumption, customizable installation options, and automated operation. These features collectively contribute to improved treatment outcomes, reduced operational costs, and enhanced equipment longevity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free