Industrial Wastewater Clarifier

Product Details:

- Power Consumption 5 25 kW (depending on capacity)

- Noise Level <70 dB(A)

- Recycle Rate Up to 99%

- Frequency 50 Hz

- Usage & Applications Dyeing, Food Industry, Chemical Plants, Textile, and Metal Processing

- Flow Rate Adjustable, up to 200 m/hr

- Efficiency (%) Up to 95%

- Click to view more

Industrial Wastewater Clarifier Price And Quantity

- 1 Plant

- 10000 INR/Unit

- Automatic/Manual

- 200 mm 700 mm (depends on model)

- Meets CPCB & Pollution Control Board Standards

- PLC Based Automatic Control

- Up to 15 m (customizable)

- Primary & Secondary Optional

- Available in Drive Motor

- 5C to 55C

- Epoxy/Polyurethane for Corrosion Protection

Industrial Wastewater Clarifier Product Specifications

- 6.5 8.5

- Up to 95% suspended solids removal

- Low Maintenance, Corrosion Resistant, High Efficiency

- <50 S/cm

- 380V - 415V, 3 Phase, 50 Hz

- Gravity Sedimentation, Sludge Removal

- 500 2000 S/cm

- Industrial Wastewater Clarifier

- Ranging from 5 m/hr to 200 m/hr

- Electric

- Centrifugal / Submersible Pump

- Customizable (from 5 m to 200 m per hour)

- Automatic

- <70 dB(A)

- No media filter

- Mild Steel with Epoxy Coating

- Industrial Wastewater

- 5 25 kW (depending on capacity)

- Adjustable, up to 200 m/hr

- Up to 95%

- Up to 99%

- Centre Driven

- Dyeing, Food Industry, Chemical Plants, Textile, and Metal Processing

- 50 Hz

- Horizontal / On-Site Installation

- Automatic/Manual

- 200 mm 700 mm (depends on model)

- Meets CPCB & Pollution Control Board Standards

- PLC Based Automatic Control

- Up to 15 m (customizable)

- Primary & Secondary Optional

- Available in Drive Motor

- 5C to 55C

- Epoxy/Polyurethane for Corrosion Protection

Industrial Wastewater Clarifier Trade Information

- Per Day

- Days

- Yes

- All India

Product Description

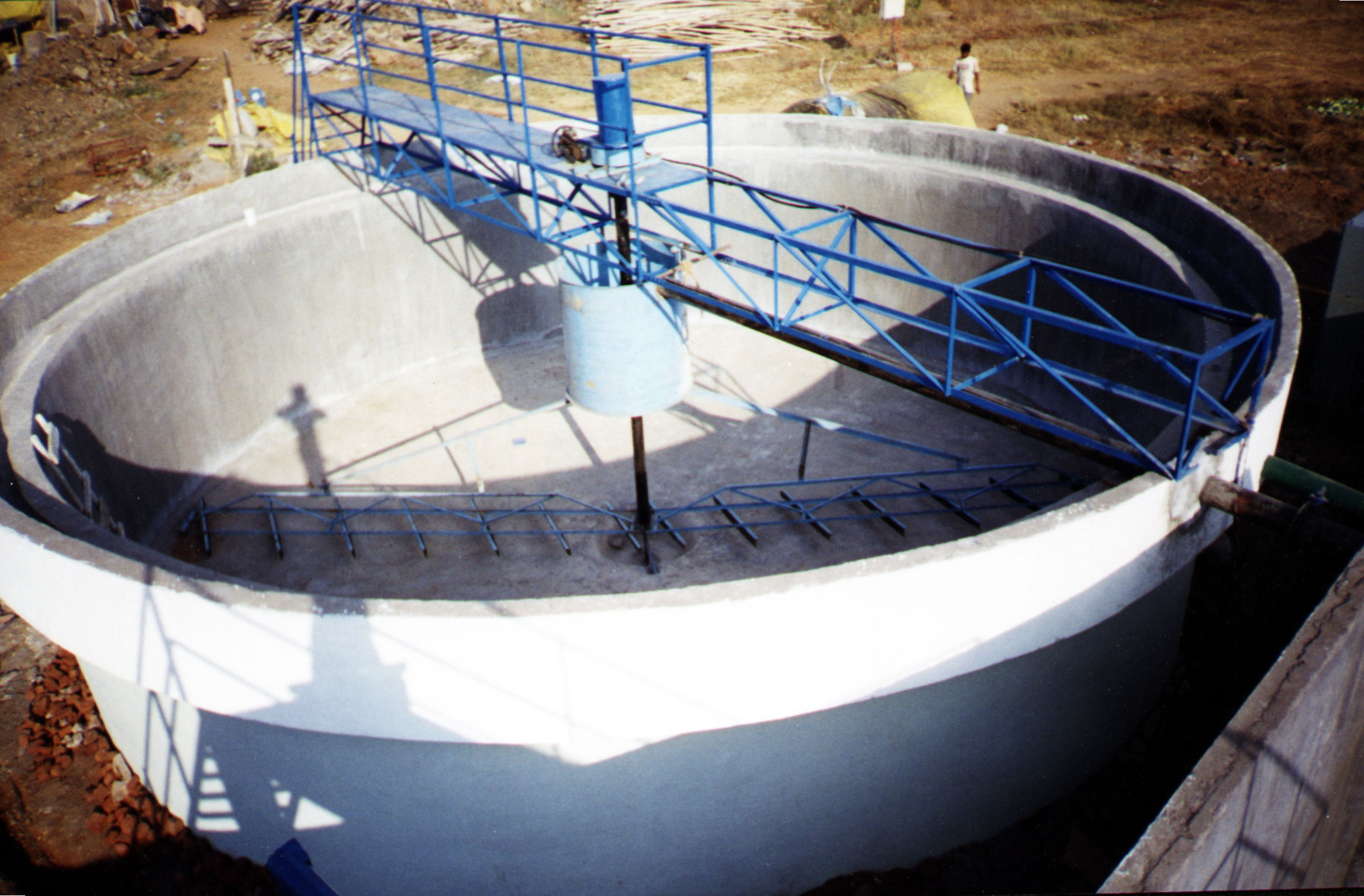

Clarifier drive unit consisting of worm and worm wheel gear unit connected to standard gear box by means of sprocket and chain arrangement and the gear box connected directly to motor mounted on MS fabricated base frame.

superstructure comprising of steel structural bridge spanning the entire diameter of the tank. The drive unit is fixed at the center of the bridge and the bridge is designed to take the static and dynamic load of the drive unit.Necessary chequered plate and hand rails is provided on the bridge so that it can be used as walkway to have access to the drive at the centre.

Two structural steel rake arms are connected to the centre shaft.The rake arms are provided with blades and adjustable brass/neoprene squeezes to rake the tank bottom twice per revolution.

The bottom of the shaft rests on guide bearing fixed to the tank cone.Suitable cone scrappers are provided.

Feed well of suitable diameter is fixed to the bridge is also provided to introduce the feed into the clarifier.

Necessary weir plates along with fixing bolts to be fixed to the outlet launder can also be provided if required.

Floating scum scrapper with scum box,high torque switch can also be provided if required.

The skimming mechanism, if required, can be provided by us. Generally, this mechanism is required to remove floating debris, a solid, which floats on effluent surface.

Efficient and Reliable Sedimentation Technology

This clarifier integrates advanced gravity sedimentation technology, which ensures high-efficiency removal of suspended solids from various industrial wastewaters. The optimized design allows for both primary and secondary clarification, supported by a customizable sedimentation area, ensuring adaptability for varying plant sizes and contaminant loads.

Automatic Operation and Control Flexibility

With a PLC-based automatic control system and options for manual operation, users benefit from a high level of customization and ease of use. Automatic and manual sludge discharge modes provide flexibility in operation, catering to the specific needs of different industries and effluent characteristics.

Durable and Corrosion-Resistant Construction

Constructed from mild steel coated with epoxy or polyurethane, this clarifier offers excellent corrosion resistance and long service life even in aggressive industrial environments. The robust drive motor incorporates overload protection, ensuring safety and reliability throughout continuous operation.

FAQ's of Industrial Wastewater Clarifier:

Q: How does the Industrial Wastewater Clarifier enhance water purity in industrial applications?

A: This clarifier uses gravity sedimentation technology to remove up to 95% of suspended solids, delivering water with a conductivity of less than 50 S/cm. Its adaptable design allows for optimal clarification in processes such as dyeing, chemical production, food processing, and textile and metal treatment.Q: What are the configurable features of this clarifier, and how do they benefit industrial users?

A: The clarifier's surface area for sedimentation (up to 15 m2), inlet/outlet sizes (200 mm - 700 mm), flow rate (up to 200 m3/hr), and sludge discharge mode (automatic/manual) are fully customizable. This adaptability ensures seamless integration with various facility sizes and specific wastewater profiles.Q: When should automatic versus manual sludge discharge be utilized?

A: Automatic sludge discharge is suitable for continuous or high-load operations, promoting efficiency and reducing labor requirements. Manual sludge discharge is recommended for smaller facilities or where process monitoring requires operator intervention, ensuring flexibility in operation.Q: Where can this clarifier be installed, and what are the installation options?

A: The clarifier supports horizontal or on-site installation, making it suitable for new constructions or retrofitting existing wastewater treatment plants in a wide range of industries across India and abroad. The versatile installation options enhance compatibility with facility layouts.Q: What process does the clarifier follow to treat industrial wastewater?

A: Industrial wastewater enters the clarifier, where gravity promotes sedimentation of suspended particles. The clarified water is then released through an adjustable flow system, while sludge is collected and removed via either an automatic or manual discharge mechanism.Q: Which industries commonly use this clarifier, and what are its primary advantages?

A: This clarifier is widely applied in dyeing, food manufacturing, chemical production, textile, and metal processing industries. Key advantages include high suspended solids removal efficiency (up to 95%), low maintenance needs, strong corrosion resistance, and full compliance with CPCB and Pollution Control Board standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free